Table of Contents

The brake is an essential control device in a car. If something goes wrong with the brakes, it can be disastrous. The following are the requirements for proper brake operation.

1. They must be strong enough to stop the car at a minimum distance in an emergency. In addition, the driver must be in control of the car when the brakes are applied due to an emergency.

2. The brakes must be applied repeatedly to slow down the cars. With repeated application of the brakes, your efficiency shouldn’t decrease. Repeated application of the brakes causes an increase in temperature which in turn causes a reduction in the coefficient of friction of the brake pad material. However, the coefficient of friction is restored as the temperature drops.

One of the basic requirements of brakes is that their efficiency does not decrease even after repeated use. This is known as the “anti-fade” function. The brakes must have good “anti-fade” characteristics. When the car goes downhills, there may be a constant and prolonged application of the brakes.

Even under these conditions, the effectiveness of the brakes should not be reduced. This can be achieved by providing efficient brake cooling.

FACTOR THAT AFFECTS THE APPLICATION OF THE BRAKES

The effectiveness with which the brakes are applied is determined by the following factors:

Pressure

The friction generated between the two surfaces in contact depends in part on the force exerted. In automobiles, the fluid in the cylinder exerts the force necessary to create friction. This force causes the brake shoes to come into contact with the steering wheel drum.

Coefficient of friction

The amount of friction between two contacting surfaces depends on the coefficient of friction. The higher the value of the coefficient of friction, the greater the amount of friction. However, the maximum value of the coefficient of friction is limited to one and depends on the properties of the material and the roughness of the surface.

With repeated application of the brakes, the surface becomes smooth. The friction coefficient is reduced and with it, the friction force is also reduced. If this happens, the brake shoes are replaced with new ones that have a rough surface. The coefficient of friction is equal to the force required to pull an object divided by its weight.

Contact area

The frictional force depends on the contact area. The larger the contact area, the greater the force. The area can be increased by increasing the size of the rim brakes and placing them on all four wheels.

Heat dissipation

When the brakes are applied, the lost kinetic energy is converted into heat. The heat thus produced must be dissipated. Otherwise, you can damage the brake shoes and other components located nearby. This heat is dissipated with the help of the air passing through the wheel.

BRAKE SEAL MATERIAL

The brake pads are made of the friction material and are attached to the brake shoes. These can be riveted or attached to the shoe. Sometimes these are shaped as an integral part of the brake shoe. Asbestos has long been used as a friction material in coatings. Recently, its use has been restricted and even banned in some countries due to health risks.

The asbestos cladding material has been replaced by all-metal, semi-metallic and non-asbestos cladding materials. Sintered iron has been used as an all-metal cladding material and is best suited for racing and heavy-duty vehicles. These require very high pedal pressure. In addition, the wear of the drums is faster. Semi-metallic coating materials have good friction and anti-fading characteristics.

These are made of cast iron fibre with adhesives. Cladding materials that do not contain asbestos are synthetic materials. Efforts are being made to improve its durability, friction characteristics, wear characteristics and heat dissipation.

Brake requirements:

1. Anti-fading features

2. Braking torque

3. Braking distance

4. Brake safety

5. Coefficient of friction

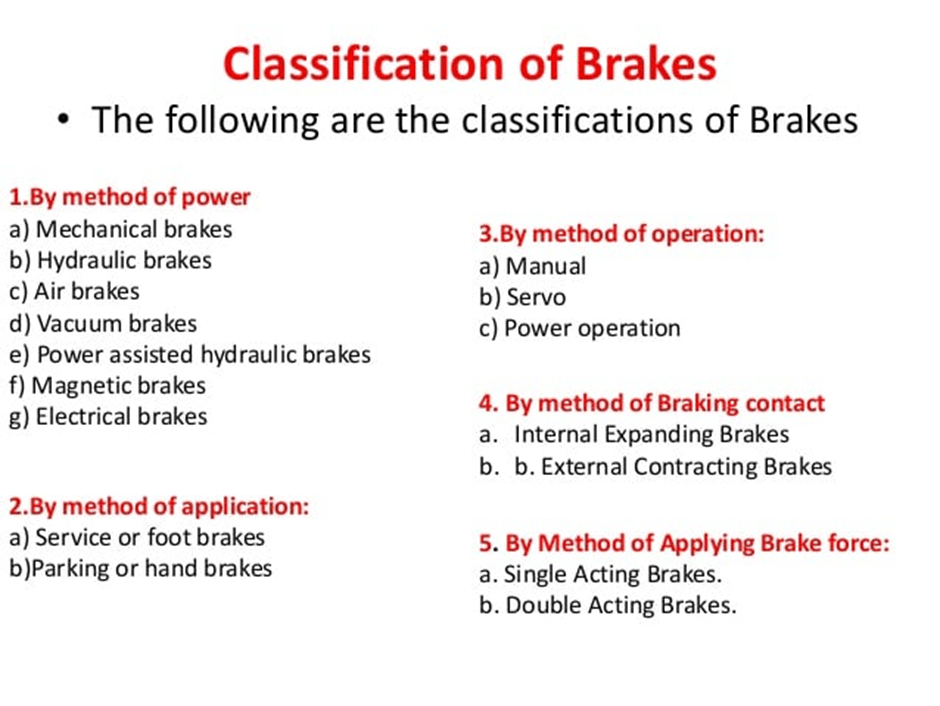

Classification of Brakes

Comments on “Requirements of Brake System in Automobiles”